Modern data centers and mission-critical facilities treat the utility grid as inherently unreliable. The grid experiences voltage sags, spikes, frequency drift, harmonic distortion, and full outages. For environments that require 99.999% uptime, raw utility power is unacceptable.

A UPS (Uninterruptible Power Supply) is the first and most important layer of protection. It is not an emergency generator and does not provide long-duration energy. Instead, the UPS acts as a bridge, holding the load steady during power disturbances and providing continuous, conditioned power until generators start and take over.

Core Functions of a UPS

In a critical facility, the UPS performs three distinct engineering functions that work in unison to protect downstream equipment.

1. Power Continuity and Bridging

The primary role of the UPS is to bridge the gap between a utility failure and the availability of backup generation. When the grid fails, standby generators typically require 10 to 30 seconds to start, synchronize, and accept the load. Without a UPS, this gap would result in an immediate “hard crash” of all IT equipment. The UPS provides instant energy—ranging from seconds (flywheel) to minutes (battery)—to ensure the load sees absolutely no interruption during this handover.

2. Power Conditioning

Sensitive loads such as servers, medical imaging devices, and industrial PLCs require precise power quality. The UPS acts as an active filter against grid anomalies. It regulates output voltage to within ±2-3% and frequency to within ±0.1Hz, while simultaneously filtering out damaging harmonics and transient spikes that could degrade hardware components over time.

3. Electrical Isolation

In double-conversion systems, the UPS electrically isolates the critical load from the utility grid. This means that faults on the utility side—such as lightning strikes or switching surges—are effectively blocked by the UPS rectification process and never reach the sensitive equipment downstream.

Main Components of a UPS

While internal architectures differ between manufacturers, most mission-critical UPS systems rely on four core components to function.

1. The Rectifier:

The Rectifier is the entry point of the system. It converts the incoming AC utility power into regulated DC power. This stage is crucial because it acts as the “firewall” for power quality; utility frequency shifts and voltage spikes are eliminated here because they cannot pass through the DC link.

2. The Energy Storage System:

The Energy Storage System serves as the fuel tank for the “bridge.” In most systems, this is a bank of VRLA (Lead-Acid) or Lithium-Ion batteries charged by the rectifier. In rotary systems, this is a high-mass spinning flywheel storing kinetic energy.

3. The Inverter:

The Inverter is the exit point. It takes the DC power—either from the rectifier during normal operation or from the batteries during an outage—and converts it back into a perfectly clean, regulated AC sine wave to feed the critical load.

4. The Inverter:

Finally, the Static Bypass Switch acts as an automatic safety valve. If the UPS detects an internal fault (such as an inverter failure) or an overload (such as high inrush current), this high-speed switch closes in less than 4 milliseconds to route raw utility power directly to the load, preventing a system crash.

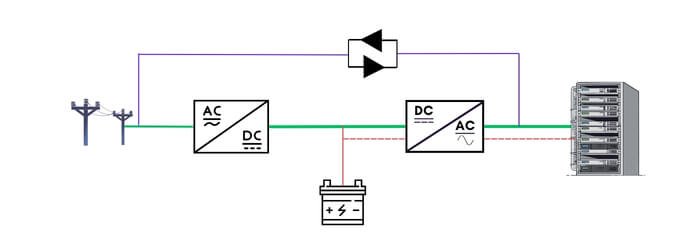

Visualizing Operations: Diagram Analysis

Referring to the attached diagram, we can trace the power flow through the three primary operational states of a standard Double-Conversion UPS.

Online Mode (The Green Line):

This represents normal operation. In this state, power flows from the Utility to the Rectifier, and then through the Inverter to the Load. The significant engineering concept here is “Double Conversion”—the load is running on power manufactured by the Inverter, not power from the street. This ensures complete isolation.

Battery Mode (The Red Line):

This is the “Bridge” state. Upon utility failure, the Rectifier shuts down, and the Inverter instantly draws energy from the Battery bank. Because the battery is permanently connected to the DC bus, there is zero transfer time. The Inverter continues to supply a perfect sine wave to the load until the generator starts or the battery depletes.

Bypass Mode (The Blue Line):

This represents a vulnerable state. If the UPS fails or is taken offline for maintenance, power flows from the Utility through the Static Switch directly to the Load. In this mode, the “filter” is removed, and the load is exposed to raw utility power.

Common Types of UPS Systems

To clarify the market landscape, UPS systems are classified into four distinct architectures based on their energy storage and power generation methods.

A. Static UPS (Battery-Based)

This is the most common architecture found in data centers. It utilizes solid-state power electronics (IGBTs) for conversion and chemical batteries for energy storage.

- Strengths: Provides the cleanest output power, rapid response times, and is highly scalable for IT environments.

- Limitations: Requires strict temperature control for the batteries and regular replacement cycles every 3–7 years.

- Top 3 Manufacturers:

B. Flywheel UPS (Rotary Kinetic)

Instead of chemical batteries, this system uses a high-speed rotating flywheel (a mechanical battery) spinning in a vacuum to store energy.

- Strengths: Offers a 20+ year lifespan, requires very low maintenance, handles high temperatures, and eliminates chemical disposal issues.

- Limitations: Provides very short runtime (15–60 seconds), meaning the backup generator must be highly reliable.

- Top 3 Manufacturers:

- Piller Power Systems

- Active Power

- Hitzinger

C. Hybrid UPS Systems

This architecture balances the benefits of Static and Rotary systems. It utilizes the static electronics (Rectifier/Inverter) of a standard UPS but replaces the maintenance-heavy chemical battery bank with a kinetic Flywheel cabinet.

- Strengths: Eliminates the fire risk and replacement costs of chemical batteries while retaining the precise voltage and frequency regulation of static electronics.

- Top 3 Manufacturers:

- Schneider Electric

- Eaton

- Piller Power Systems

D. DRUPS (Diesel Rotary UPS)

A DRUPS is a heavy-industrial machine that combines a UPS and a Diesel Generator on a single mechanical shaft.

- Strengths: Provides unlimited runtime (constrained only by fuel supply) and high power density, making it ideal for hyperscale facilities.

- Limitations: Involves complex mechanical maintenance, noise, and exhaust management.

- Top 3 Manufacturers:

- Piller Power Systems

- Hitzinger

- Rolls-Royce / MTU

Engineering Specifications and Capacity

When specifying a UPS, engineers must look at both capacity and voltage levels. Systems are rated in kVA (Kilovolt-Amperes). Small units (1–10 kVA) typically support office equipment, while medium units (10–500 kVA) support server rooms. Large-scale data centers utilize multi-megawatt systems.

Voltage standards vary by region and application. In North America, 480V or 208V is standard, while Europe and Asia utilize 400V/230V. Large industrial campuses may employ Medium Voltage (MV) UPS systems ranging from 3.3kV to 13.8kV to reduce cabling costs.

Why UPS is Critical in Mission-Critical Facilities

The value of a UPS extends beyond simple backup. In data centers, the cost of downtime can average between $5,000 and $150,000 per minute. A UPS prevents data corruption by ensuring that write operations and transactions are never interrupted mid-stream. Furthermore, it protects hardware; the “hard crash” caused by a sudden power loss can damage drive heads and corrupt file systems. By smoothing the transition to generator power, the UPS ensures that the facility operates as a continuous, cohesive system rather than a collection of vulnerable components.

Selection and Maintenance

Selecting the right UPS requires matching the architecture to the application criticality.

| Application | Recommended Type | Capacity Range | Backup Time |

| Home/Small Office | Offline / Line-Interactive | 500VA – 2kVA | 5–10 Minutes |

| Medium Business | Line-Interactive / Online | 5kVA – 10kVA | 15–30 Minutes |

| Data Center | Static Online (Double Conversion) | 20kVA – 100kVA+ | 30–60 Min + Ext. Battery |

| Hyperscale / Industrial | DRUPS or Parallel Online | 500kVA – 10MVA+ | Unlimited (with fuel) |

Once installed, maintenance is non-negotiable. Batteries are the single most common point of failure. Best practices include monthly visual inspections, quarterly load testing, and annual thermal imaging of breakers and connections. Lead-acid batteries should generally be replaced every 3–5 years, while Lithium-Ion units may last 10–15 years.

Mission Critical Engineers Ltd.

Your trusted expert for UPS systems, power infrastructure, data centers, and all mission-critical electrical engineering needs.

If you need design, consulting, upgrade studies, procurement support, or fault-analysis for any UPS technology (Static, Rotary, or Hybrid), we provide end-to-end solutions.

Contact us to discuss how we can support your facility’s reliability and uptime.