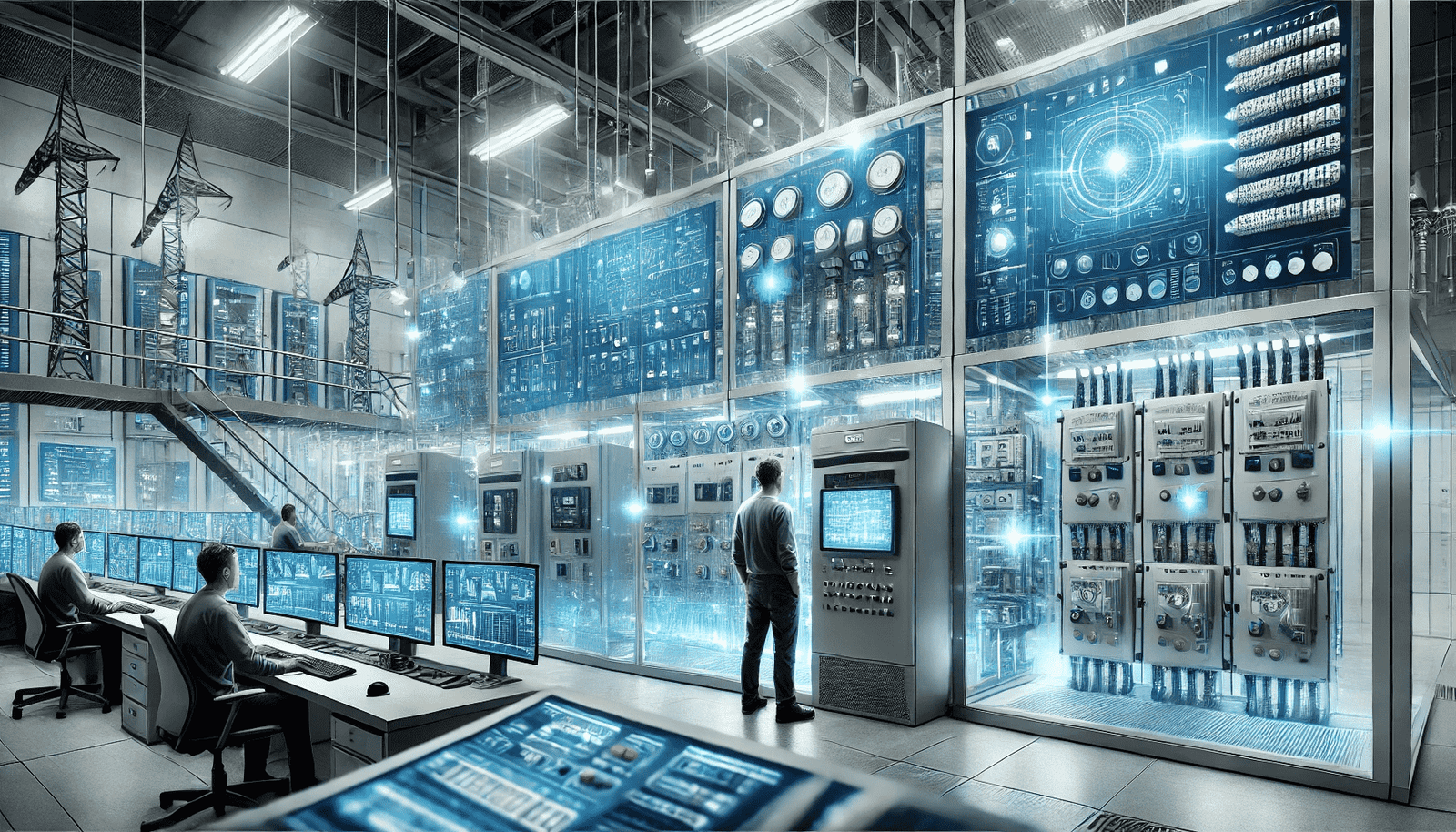

In today’s digital age, power isn’t just about keeping the lights on – it’s the lifeblood of our most critical systems and infrastructure. From bustling data centers that keep our digital world spinning to hospitals where every second of uptime can mean the difference between life and death, the stakes have never been higher when it comes to electrical reliability and protection.

But are you truly ready to serve and protect in these high-stakes environments? Let’s dive into the world of advanced electrical system protection, where safety, continuity, and efficiency aren’t just goals – they’re absolute necessities.

The Power Behind the Digital Curtain

Every time you stream a video, send an email, or make an online purchase, you’re relying on vast networks of servers humming away in data centers. These digital fortresses are the backbone of our modern world, but they’re incredibly vulnerable to one critical factor: power disruptions.

Even a millisecond of downtime in a data center can result in:

- Lost data

- Interrupted services

- Significant financial losses

- Damage to expensive equipment

This is where robust electrical system protection comes into play. It’s not just about preventing outages – it’s about ensuring the continuous, clean power supply that sensitive electronic equipment demands.

Understanding the Basics: The Goals of Electrical Systems

All electrical systems share a common goal: to provide electrical energy in the form of current (A) at a specific voltage level (V) to the end user or equipment in a safe, reliable, and economical manner. This objective leads to two fundamental requirements in designing electrical systems for power distribution:

- Adequacy: Ensuring the system can supply sufficient power to meet demand.

- Reliability: Minimizing outages and damage, particularly during abnormal conditions.

Today, we’re focusing on the second requirement – electrical system protection – a critical component that safeguards lives, prevents fires, protects valuable equipment, and ensures continuous operation.

The Hierarchy of Protection: More Than Just Keeping the Lights On

The general priorities in electrical protection are as follows:

- Prevent injuries: The paramount concern is human safety. Measures such as electric shock prevention and arc flash protection are crucial to safeguarding personnel.

- Prevent fires: Electrical fires can be devastating. Protection systems are designed to detect and mitigate conditions like overheating or arcing that could lead to fire.

- Minimize equipment damage: Protecting valuable electrical equipment from faults or abnormal conditions is key to maintaining operational integrity and reducing costs.

- Ensure Continuity: Power continuity is vital in most applications, as downtime can result in significant economic losses or operational problems.

In mission-critical environments like data centers and hospitals, minimizing downtime is equally important. In such environments, redundancy and rapid fault isolation are essential to maintain near-continuous power availability, while still prioritizing safety and fire prevention.

The Villains of the Electrical World: Common Abnormal Conditions

To truly appreciate the importance of electrical protection, it’s essential to understand the abnormal conditions it guards against. These include:

- Overload: When equipment draws more current than a circuit can handle, it overheats, potentially causing insulation damage and fires. Real-world example: In a commercial building, an overloaded circuit could overheat wiring in the walls, posing a fire hazard.

- Short circuits: A short circuit occurs when two live conductors come into direct contact, causing a surge in current. This can melt wires, destroy equipment, and cause fires. Real-world example: A short circuit in an appliance could destroy it and pose a fire risk to the surrounding environment.

- Under voltage: Insufficient voltage can cause equipment to malfunction or motors to overheat. Systems designed to work at specific voltage levels may shut down or fail when voltage drops. Real-world example: Under voltage in a factory setting could cause motors to stall, leading to production halts.

- Loss of phases: In three-phase systems, losing one phase creates imbalance, leading to mechanical stress on motors and other equipment. Real-world example: A phase loss in a manufacturing plant can cause motor failure and production delays.

- Overvoltage: Excessive voltage stresses insulation and damages equipment. Real-world example: During a lightning storm, overvoltage could damage sensitive equipment, causing data loss in a data center.

- Frequency deviations: Frequency-sensitive equipment can malfunction or operate inefficiently when system frequency deviates from the norm (50Hz or 60Hz). Real-world example: Frequency fluctuations could lead to erratic performance in industrial machines, resulting in inconsistencies.

Guardians of the Grid: Key Protection Measures

To address these abnormal conditions, various protection measures are employed:

Overcurrent Protection Devices:

- Circuit breakers: Automatically disconnect circuits when detecting overloads or short circuits, preventing damage.

- Fuses: Melt when excess current flows, breaking the circuit and protecting equipment.

- Relays: Detect abnormal conditions and trigger other protection devices, such as circuit breakers, to isolate the fault.

Voltage Protection:

- Surge protectors: Divert excess voltage to ground, protecting equipment from transient overvoltages.

- Voltage regulators: Maintain consistent voltage levels despite input fluctuations, ensuring stable power supply to equipment.

Ground Fault Protection:

- Ground fault circuit interrupters (GFCIs): Disconnect power when current leakage to ground is detected, preventing electric shock.

- Ground fault protection relays: Monitor for ground faults in larger systems, triggering protective actions.

Differential Protection:

Used for detecting internal faults in transformers and generators by comparing input and output currents. It protects these high-value components from internal faults.

Distance Protection:

Primarily used in transmission lines, distance protection detects faults by measuring impedance and rapidly isolates the faulty sections, reducing downtime and preventing further damage.

Thermal Protection:

- Thermal overload relays: Estimate equipment temperature based on current and disconnect circuits when overheating is detected.

- Temperature sensors: Directly measure equipment temperature and trigger protective actions when thresholds are exceeded.

Arc Flash Protection:

- Arc flash relays: Detect the intense light from an arc flash and interrupt the circuit rapidly to prevent injury and equipment damage.

- Personal protective equipment (PPE): Essential for personnel safety in environments where arc flash is a risk.

Key Takeaways

- Safety First: Electrical protection ensures the safety of personnel by preventing injuries from electric shock or arc flash incidents.

- Prevent Fires: Protection systems play a critical role in minimizing the risk of electrical fires caused by overloads, short circuits, and other faults.

- Preserve Equipment: Implementing proper protection can significantly reduce equipment damage, lowering maintenance and replacement costs.

- Ensure Continuity: Minimizing downtime is crucial in mission-critical environments. Effective electrical protection ensures that faults are isolated quickly, keeping systems operational.

Designing Robust Electrical Systems

Designing an electrical system that adequately delivers power and is well-protected against all faults requires a deep understanding of electrical engineering principles, safety standards, and the specific requirements of the application. It involves careful planning, from load calculations and equipment selection to the integration of various protection devices and systems.

As electrical systems become more complex and the demand for reliability increases, staying updated with the latest protection technologies and best practices is crucial. Whether you’re designing a new system or upgrading an existing one, ensuring proper protection is not just about compliance—it’s about creating a safe, efficient, and reliable electrical infrastructure.

If you’re looking to deepen your understanding of electrical system design and protection, consider seeking specialized training or consulting services. Professional guidance can provide valuable insights into optimizing your electrical systems for both performance and safety. For those interested in one-on-one training or consulting on electrical system design and protection, feel free to reach out. With personalized guidance, you can gain the expertise needed to create robust, efficient, and well-protected electrical systems tailored to your specific requirements.